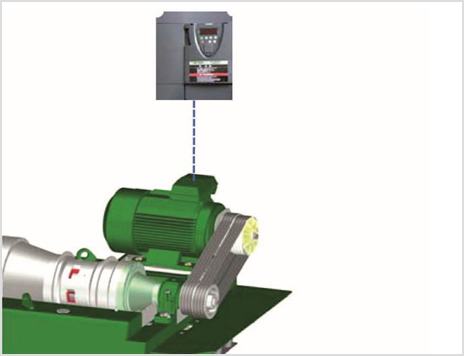

Bowl and Scroll is driven by one Electrical Motor and 2 V-Belt Drives. The Scroll is driven by a rotating Cyclo Gearbox whose design is patented by us and imported from Germany. For Fluid/Turbo Coupling systems, the differential speed is adjusted by changing pulley diameters.

A DOL Panel in this case is supplied for starting and stopping the machine. For a VFD system, the differential speed can be adjusted by changing pulley diameters and adjusted automatically for minor feed variations, by altering the frequency of the motor via the VFD. Our VFDs are enclosed in a Control Panel based on our wiring scheme.

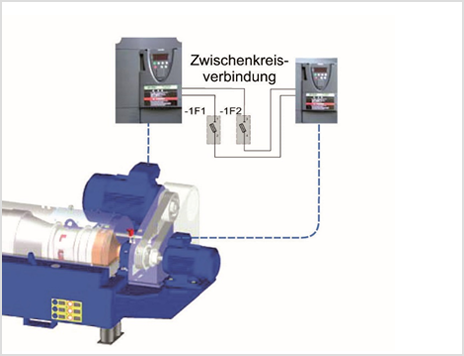

These are our fully automated machines where bowl and scroll drives are independently drives by 2 electric motors and 2 VFDS. For a Back Drive System, a single Planetary Gearbox, which is patented and imported from Germany, interdependently controls the bowl and scroll drives together.

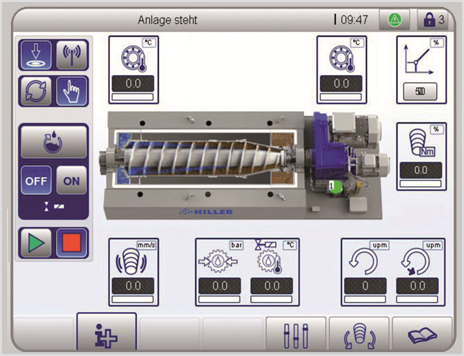

The bowl and scroll speeds can be adjusted manually and via automatic feedback to adjust the differential speed, so as to give optimal separation, regardless of the changes to sludge/slurry consistency. Our machines with this drive system is supplied with our Control Panel with Hiller GmbH Germany's own designed and patented Hiller SEE Control touch screen PLC .

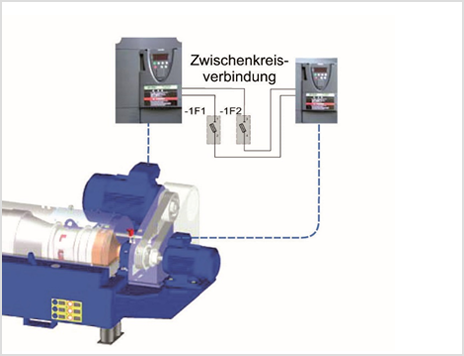

For our highly energy efficient Differential Drive System, 2 Cyclo Gearboxes, which are patented and imported from Germany, independently control the bowl and scroll drives. Since the bowl and scroll are independent of each other, hence greater optimisation in separation can be achieved. This drive system makes our machines fully automated in nature, which means that with vast changes at inlet feed conditions the resultant cake dryness after separation will remain optimised and constant.

Our machines with this drive system is supplied with our Control Panel with Hiller GmbH Germany's own designed and patented Hiller SEE Control touch screen PLC .

This is a fully automated drive system, which uses Hiller GmbH Germany's patented Hydraulic Drive Unit to individually control both the bowl and scroll drives. This is a high torque (20% higher than all other systems) drive system used for application with extremely high solid load in sludge/slurry.

Our machines with this drive system is supplied with our Control Panel with Hiller GmbH Germany's own designed and patented Hiller SEE Control touch screen PLC .

Imported from our Parent Organisation, this is our own designed and patented electronic control system, with a 7.5 inch infrared touch screen display. This is enclosed in a Control Panel based on our wiring scheme. This permits control of the entire Decanter Centrifuge system along with it's ancillary equipment and all supporting electronic instruments.